Scaling from Single Facility to Multi-Facility Operations: Grow Without Replatforming

Many distributors begin small, working from a garage, a cargo van, or a single warehouse. Growth brings a critical moment: expanding to a second location. This transition breaks most inventory systems.

The same software that worked perfectly for one warehouse suddenly can't handle two. The spreadsheet that tracked garage inventory falls apart when you add a mobile unit. Simple systems force painful migrations. Enterprise platforms demand six-figure investments.

Opalfi takes a different approach. Our software adapts to your growth, revealing advanced capabilities like multi-location transfers precisely when you need them, not before.

What 'Facility' Means in Practice

A facility is any location where you manage stock. This could be your main warehouse, an overflow storage unit, a garage, a cargo van, or even a micro depot. Opalfi treats every location as a first-class facility, complete with its own inventory counts, permissions, and transfer capabilities. Our software adapts to your operational reality, whether you're managing a large distribution center or a single plumber's van.

The Growth Inflection Point

Expanding to multiple facilities delivers clear benefits: closer customer proximity, reduced shipping costs, and increased capacity. Yet this growth often exposes a critical flaw in traditional inventory software.

Most operators don't realize their software is the problem. They blame their processes, their team, even themselves. "Maybe we're not ready for multiple locations," they think. But the real issue? Their software was never designed to scale.

Single-facility systems assume operations occur in one place. Add a second location and those assumptions break. Teams need to know which facility holds which stock, how to move items efficiently between sites, and how to maintain accuracy across the network. The move from one to two locations is often the hardest jump for inventory systems.

💡 The move from one to two locations tests software more than the move from two to ten. Good systems handle this inflection point gracefully.

Ready to evaluate a second location? Visit opalfi.com to learn more.

Trapped Between Too Simple and Too Complex

When single-facility software no longer keeps up, teams face a difficult choice. Basic systems lack multi-site visibility and transfer capabilities. Enterprise solutions offer these features but come with large upfront costs and overwhelming complexity, often built for Fortune 500 companies, not growing distributors.

This false choice leads to hidden costs: disruptive migrations, team resistance, and investment in features that go unused. Growth gets easier with systems that match actual operational complexity and evolve with the business.

Progressive Complexity Revelation

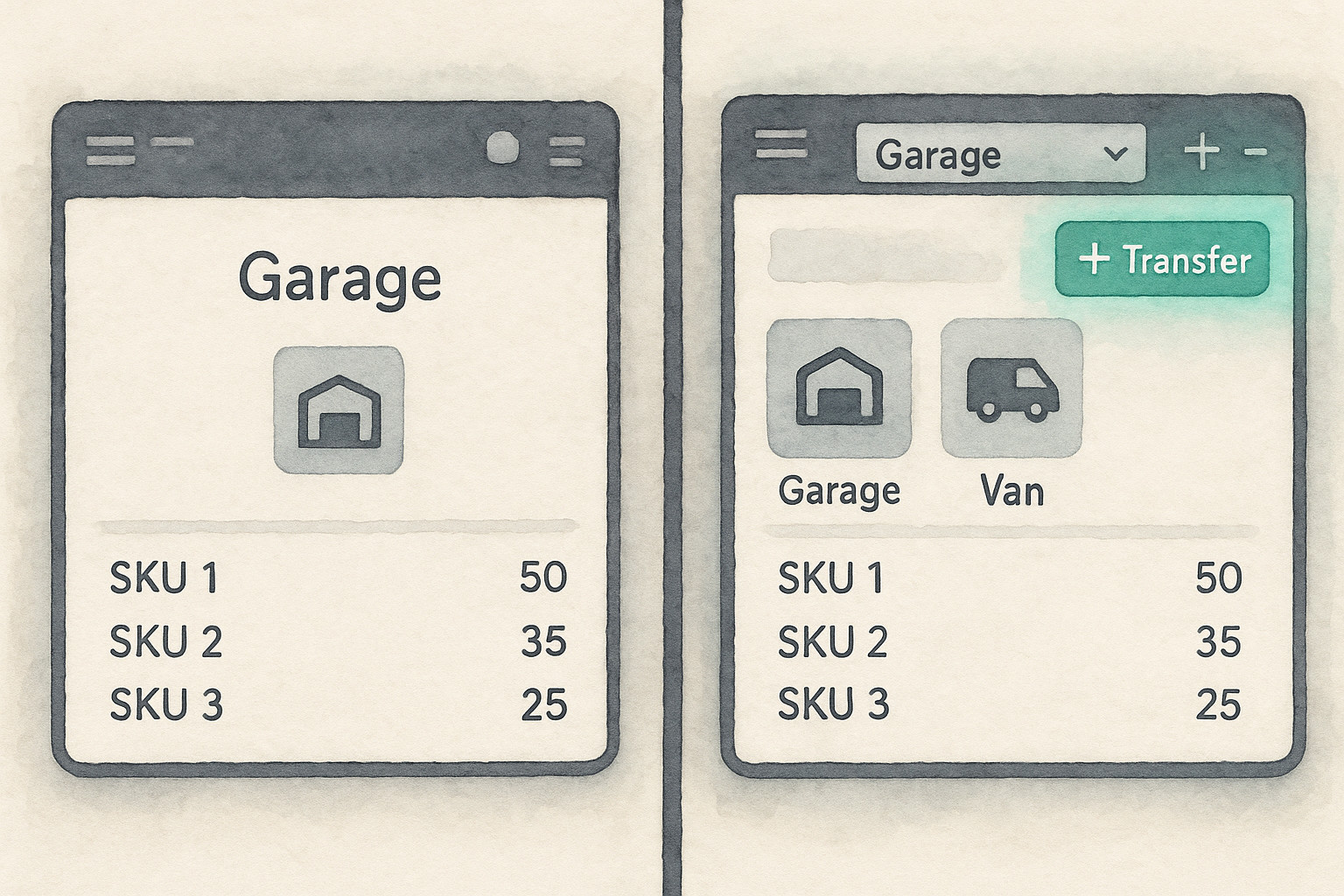

Opalfi offers a smarter approach. Start with a single location and the interface stays clean and focused on core tasks: receiving, tracking, picking, and shipping. Add a second facility and the system adapts. Transfer workflows and facility filters appear in navigation, revealing multi-facility tools precisely when operations demand them.

Hypothetical Scenario: A specialty parts distributor starts in their home garage, tracking 75 SKUs on clipboards. After switching to Opalfi, they finally have real inventory control. Six months later, business is booming. They outfit a cargo van for mobile inventory, dreading the software complexity this will add.

But when they add the van as a second facility in Opalfi, something remarkable happens: their dashboard adapts automatically. Facility filters appear. Transfer features activate. The complexity reveals itself gradually, matching their actual needs. No overwhelming enterprise features. No manual configuration. Just the right tools at the right time.

Assumptions: Single garage expanding to garage plus mobile unit within 6 months; approximately 75 active SKUs; 20 daily orders. Illustrative scenario; actual results vary by operation.

Want to see how this works in practice? Visit opalfi.com to learn more.

Common Scaling Mistakes to Avoid

Before expanding to multiple facilities, many distributors make costly mistakes that could be prevented with proper planning:

Starting enterprise software too early: Some operators, anticipating growth, invest in complex enterprise systems while still running from a single garage. They spend months in implementation, train teams on features they won't use for years, and burn through budgets on unnecessary complexity.

Delaying the transition too long: Others push their single-facility system past its breaking point, using workarounds and manual processes to fake multi-location support. This creates data silos, accuracy problems, and team frustration that takes months to untangle.

Choosing rigid facility hierarchies: Traditional systems force you to designate "main" warehouses and "satellite" locations, creating artificial limitations. Real operations are more fluid. Today's storage unit might become tomorrow's main distribution point.

The best time to upgrade your inventory system is just before you need it, not during a crisis.

Underestimating transfer complexity: Moving inventory between facilities seems simple until you try tracking it. Without proper in-transit visibility, stock disappears into black holes between locations. Teams resort to phone calls and spreadsheets, defeating the purpose of having software.

These mistakes cost time and trust while Opalfi helps you avoid them.

Balance Local Control with Network Visibility

Managing multiple facilities means balancing local control with network-wide visibility. Each location, whether a warehouse, storage unit, or van, needs its own settings, reorder points, and storage structures. Yet teams also need a unified view of inventory across all sites to make informed stocking decisions.

Opalfi delivers this balance. Each facility operates with tailored configurations: local demand-based reorder points, facility-specific user access, and unique storage layouts. Simultaneously, teams gain comprehensive cross-facility visibility for transfers, network-wide availability checks, and consolidated reporting. This architecture ensures local efficiency while enabling seamless network coordination.

Transfers That Stay Accurate, End-to-End

Moving inventory between facilities demands precision. Opalfi focuses on outcomes that keep both ends accurate:

- Clear, auditable status from request through receipt

- Picks tailored to each location's layout

- In-transit visibility with expected arrivals and variance capture

- Reconciliation that keeps both sides correct

This prevents "lost in transit" stock and keeps teams aligned.

Good inventory software should bend to business reality, whether operating from a garage or a distribution center.

- Opalfi Team

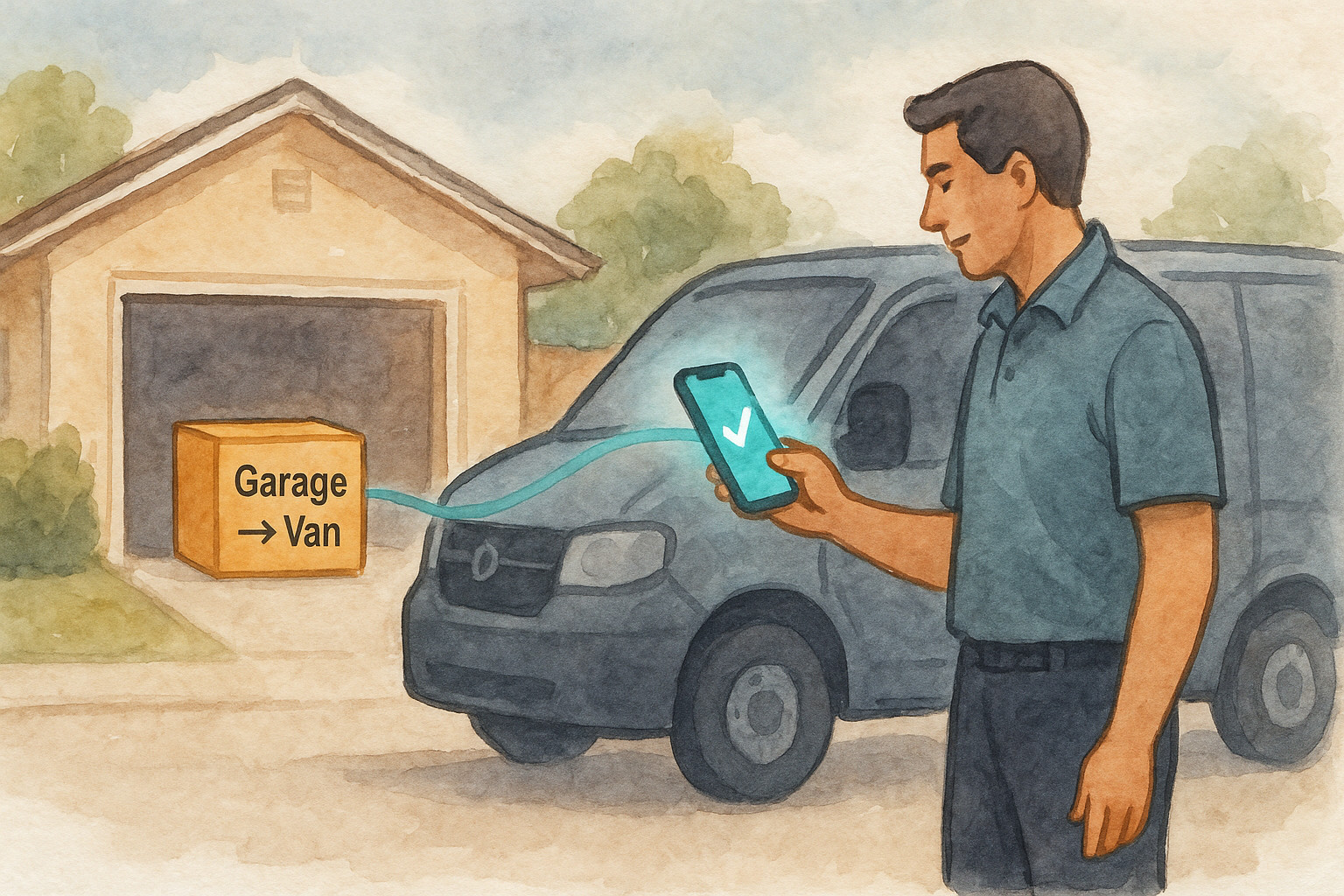

Hypothetical Scenario: It's 2 PM on a busy Monday. A plumbing parts distributor's north-side van driver realizes they're down to their last water heater element. Three service calls remain on today's schedule.

In the old days, this meant frantic phone calls to the garage, hoping someone was there to check stock. Now, the driver opens Opalfi on their phone, sees the garage has 12 units available, and initiates a transfer request for 5 units.

Back at the garage, the warehouse operator gets an instant notification. The pick list appears on their device, optimized for their garage layout. They pick, pack, and mark the items as ready. When the driver swings by at 3:30 PM, everything's waiting. The system tracks the handoff, updates both locations, and the driver heads back out fully stocked. No phone tag. No guesswork. Just smooth operations.

Assumptions: Home-based operation with 2 mobile units; 150 SKUs per van; daily restocking cycles. Illustrative scenario; actual results vary by operation.

Facility-Specific Rules That Keep You Accurate

Each location has unique needs. A main warehouse might require two weeks of safety stock, while a satellite location needs only three days. High-value items might demand bin tracking at headquarters, but zone-level tracking suffices for smaller sites.

Opalfi provides facility-level configuration without adding complexity. Set reorder points to match local demand, configure storage structures to fit each location's layout, and assign team members with appropriate permissions for specific facilities. This flexibility allows optimization of each location independently while maintaining system-wide consistency.

✅ Start with the facilities you have today, even if that's just a garage and a van. Add more sophisticated locations naturally as your business expands.

Real-World Industry Applications

Different industries face unique multi-facility challenges. Here's how adaptive inventory management addresses them:

HVAC Distributors: Seasonal demand varies dramatically by region. Your Phoenix warehouse needs different reorder points than your Denver location. During summer, Phoenix might stock 200 AC units while Denver focuses on 20. Opalfi lets each facility optimize for local patterns without forcing company-wide rules.

Food Service Suppliers: Freshness matters. Your main warehouse might hold dry goods for weeks, while satellite locations near restaurants need daily replenishment. Different facilities, different rules, one system managing it all.

Industrial Safety Equipment: Compliance requirements vary by state. Your California facility needs different documentation than your Texas warehouse. Facility-specific settings ensure each location meets local regulations while maintaining central oversight.

💡 Each industry has unique patterns. Software should recognize these differences, not force standardization.

Opalfi's adaptive approach ensures your inventory system supports these diverse operational realities.

Fast Performance from Garage to Distribution Center

Speed matters whether you run one facility or many. We've seen too many distributors suffer through systems that slow to a crawl as they grow. Every search takes longer. Every transfer creates delays. Teams start working around the system instead of with it.

Opalfi maintains responsive performance across all facility types and scales. A search across 10,000 SKUs returns as quickly as one across 100. Transfer workflows process instantly whether moving one item or one hundred.

Our API architecture supports integration without compromise. Integrations run smoothly without slowing down daily operations. Your pick-pack-ship workflow stays fast even when integrated systems are pulling reports.

The Practical Path Forward

Successful multi-facility operations thrive on a balance of local autonomy and network coordination. Your software should empower this balance. Start with the capabilities you need today, and seamlessly add sophistication as your network expands.

Recognize these signals that your operations are ready for multi-facility management:

- Regular shipments to distant regions with high freight costs

- Seasonal capacity constraints at the main location

- Customer demands for faster delivery in specific markets

- Inventory mix diverging significantly by region

When these patterns emerge, Opalfi is ready to grow with your business.

What This Means for Your Operation

Expanding from a single facility to multiple locations is a significant milestone. Inventory systems should enable that growth. With Opalfi, teams gain the precise multi-facility capabilities needed: clear transfers, facility-specific controls, network visibility, and consistent performance across locations.

We designed Opalfi based on direct experience with distributors of all sizes. We understand growth does not always mean traditional warehouses, and software must adapt to how operations truly run.

Start with the current setup. Scale seamlessly to meet tomorrow's demands. Never apologize for facility type or size.

Grow Without Replatforming

Achieving multi-facility maturity should be a natural progression, not a disruptive overhaul. Opalfi allows your team to add capabilities as your operations evolve, building upon what already works.

Next Steps

Multi-facility success isn't about having the biggest warehouses or the most locations. It's about having software that understands your actual operations, whether that's a garage today or a distribution center tomorrow.

Inventory management should stop being a constraint and become a growth enabler.

- Opalfi Vision

The path from one facility to many doesn't require enterprise software or complex migrations. It requires software that grows with you, revealing capabilities as you need them, maintaining performance as you scale, and respecting that your garage is as important as any warehouse.

Ready to see how Opalfi adapts to your multi-facility operations? Visit opalfi.com to explore our approach to scaling without replatforming.

We're actively partnering with distributors ready to grow without the pain of replatforming. Whether you're expanding from one garage to two, adding your first mobile unit, or managing a network of warehouses, Opalfi adapts to your reality.

No forced migrations. No enterprise complexity. No apologies for your facility type. Just inventory management that grows with your business.

This is part 1 of a 4-part series on scaling inventory operations. Future articles will cover team collaboration, will-call and order orchestration, and continuous monitoring for lasting accuracy.